Nickel Alloy

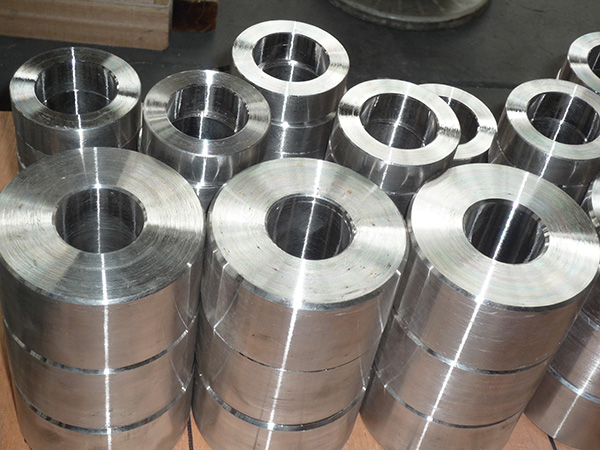

XINHUA is mainly engaged in the development and production of nickel alloys. Our products include a wide range of alloy materials that contain all kinds of element, and most of the high performance alloy with different forms can be used in various rigorous environments. During long time application in different industries, our nickel base alloy presents prominent toughness and strength as well as high temperature and corrosion resistance.

Nickel alloys excel in high temperature environments thanks to their ability to maintain structural integrity, strength and toughness at elevated temperatures, and exhibit strong corrosion resistance in acid, alkaline and chloride-containing media. They are ideal materials used in key components of jet engine, turbocharger and other products requiring remarkable high-temperature strength and fatigue resistance across a variety of industries such as aerospace, marine, power generation and automotive manufacturing.

We provide all kinds of information about nickel alloy’s physical prosperities and chemical composition in following pages where you can also get wide application information. For more information, you can contact us at any moment.

Inconel 600 Nickel Alloy

The Inconel 600 nickel alloy, a solid solution strengthened alloy with nickel, chrome and iron as principal elements

Inconel 601 Nickel Alloy

The Inconel 601 nickel alloy is a general-purpose engineering material designed for applications that require resistance to heat and corrosion.

Inconel 625 Nickel Alloy

The Inconel 625 nickel alloy is a solid solution strengthening high temperature alloy with an addition of molybdenum and niobium that can stiffen the alloy’s matrix and thereby provide high strength.

Inconel 718 Nickel Alloy

The Inconel 718 nickel alloy, with outstanding fabricability, excellent weldability and long term structure stability, can be made into complex parts used for various industries.

Incoloy 800 Nickel Alloy

The Incoloy 800 nickel alloy manufactured by XINHUA has proved itself to be an outstanding alloy material with good creep-rupture strength and great heat and corrosion resistance in years of industrial applications.

Incoloy 800H Nickel Alloy

The Incoloy 800H nickel alloy has the same basic composition asIncoloy alloy 800 but with significantly higher creep and rupture strength. It boasts excellent aqueous corrosion resistance ...

Incoloy 825 Nickel Alloy

The Incoloy 825 nickel alloy has excellent resistance to stress corrosion cracking and to pitting and crevice corrosion. In addition, the Incoloy alloy 825 is especially resistant to ...

Incoloy A-286 Nickel Alloy

The Incoloy A-286 nickel alloy is an iron-nickel-chromium alloy with additions of molybdenum, titanium, aluminum, vanadium and trace amount of boron that stiffen the alloy matrix ...

Inconel X-750 Nickel Alloy

The Inconel X-750 nickel alloy is similar to Inconel alloy 600 but made precipitation hardenable by adding aluminum and titanium and thereby shows excellent resistance to high temperature ...

Inconel 690 Nickel Alloy

The Inconel 690 nickel alloy has outstanding resistance to many corrosive aqueous media and high temperature environments. High chromium content gives alloy 690 superior corrosion ...

Monel 400 Nickel Alloy

The Monel 400 nickel alloy, a solid solution alloy manufactured by XINHUA, can be hardened only by cold processing. It shows pretty high strength and toughness over a wide range of temperatures ...

Monel K-500 Nickel Alloy

The Monel K-500 nickel alloy has the same corrosion resistance as the Monel 400 but higher mechanical strength and hardness. The strengthened properties are achieved by the additions ...

Hastelloy X Nickel Alloy

The Hastelloy X nickel alloy, with higher iron content, has favorable resistance to oxidation and corrosion combined with excellent creep and rupture strength at temperatures under 900℃ ...

Hastelloy C-276 Nickel Alloy

The Hastelloy C-276 nickel alloy boasts remarkable resistance to pitting, crevice and stress corrosion in wide range of rigorous environments. Hastelloy alloy C-276 is one of the rare materials ...

Invar 36 Nickel Alloy

Invar 36 nickel alloy has ultra low expansion coefficient at the temperature range from -250℃ to 200℃. At cryogenic temperatures, especially, Invar alloy 36 can maintain great strength and toughness...

Kovar 4J29 Nickel Alloy

The Kovar nickel alloy supplied by XINHUA has similar linear expansion coefficient with borosilicate (or Pyrex) over a range of temperatures (20℃~450℃), enabling it to be compatible with the thermal expansion...

904L Nickel Alloy

The 904L nickel alloy is a high-alloy austenitic stainless steel with low carbon content. Similar with other frequently used CrNi austenitic steel, the alloy 904L has excellent resistance to pitting and crevice corrosion...

Alloy 20 Nickel Alloy

The Alloy 20 nickel alloy is a nickel-iron-chromium alloy with additions of copper and molybdenum. The combination of limited chemical compositions contributes to its outstanding resistance to various corrosions...

pipe & tubing

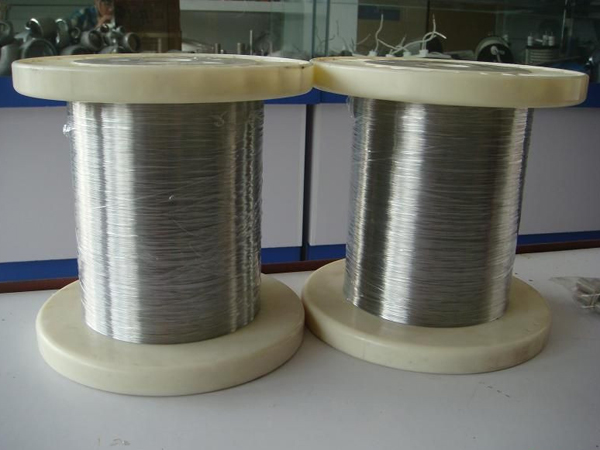

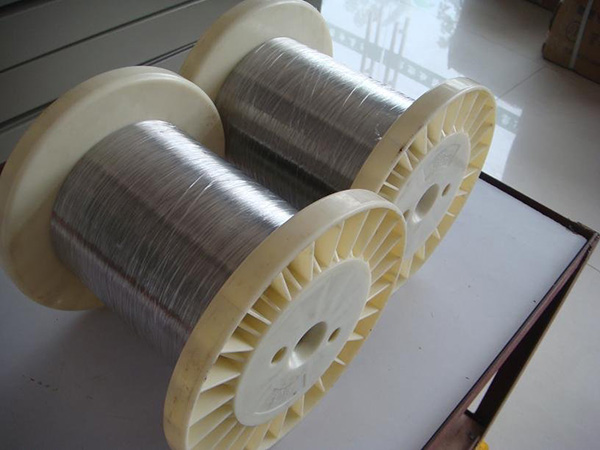

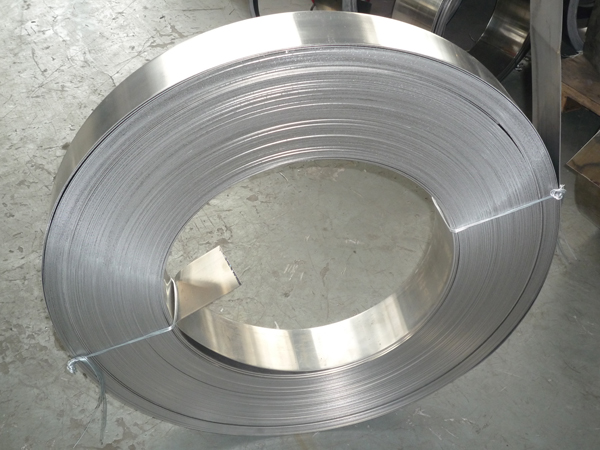

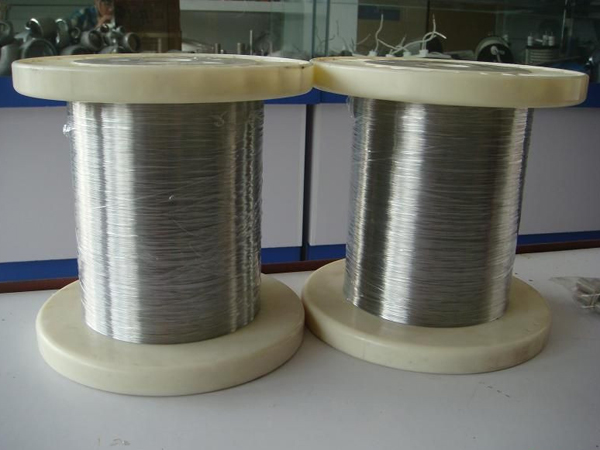

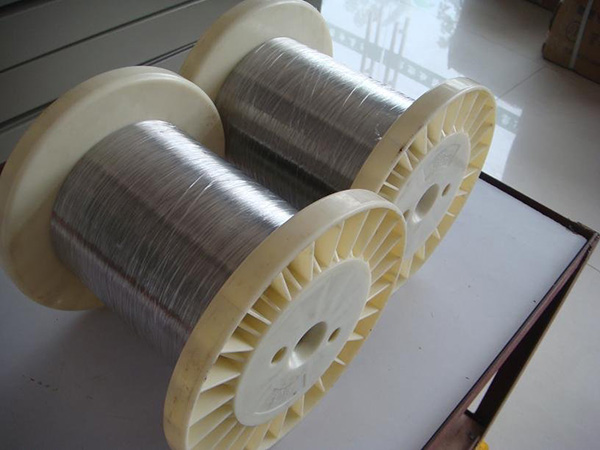

pipe & tubing wire

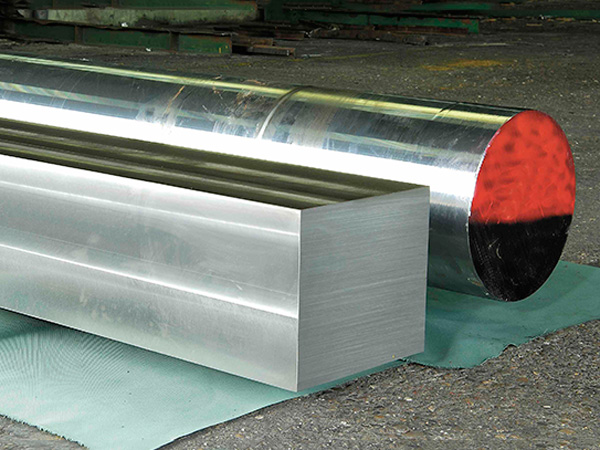

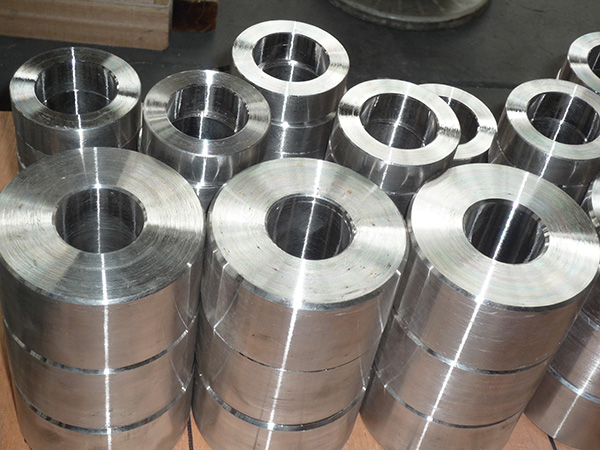

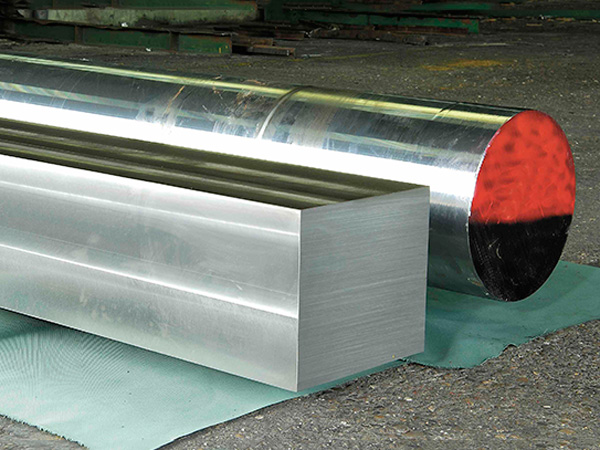

wire bar

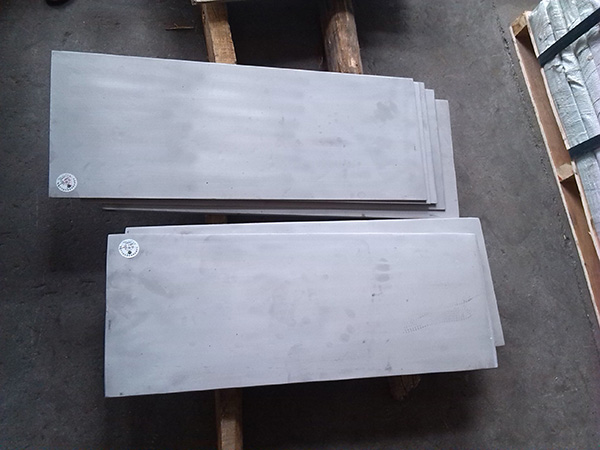

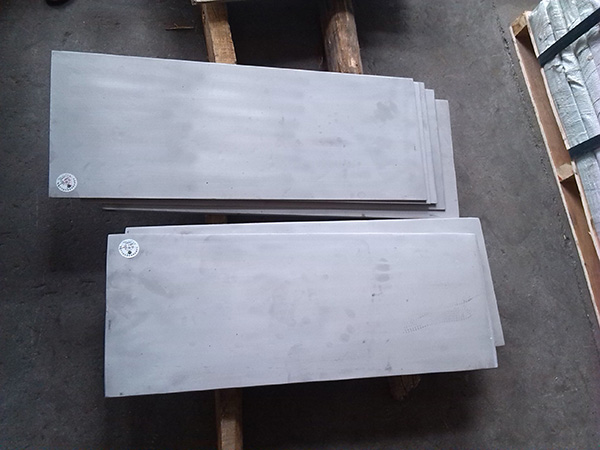

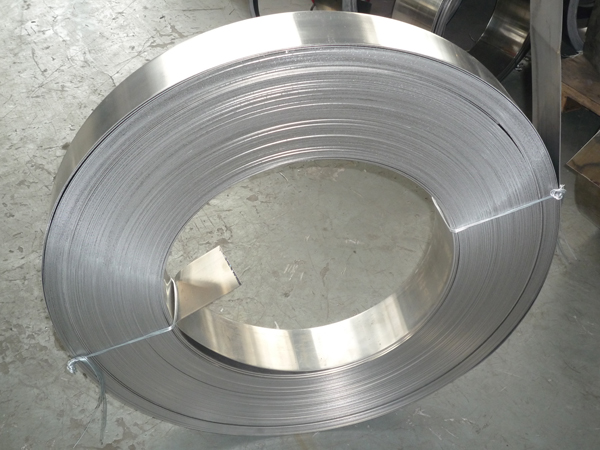

bar sheet & plate

sheet & plate