Nickel Alloy Welding Material

XINHUA offers five types of nickel alloy welding material for welding different nickel or high-nickel alloys as well as for welding and overlay welding dissimilar metals. Hence, different welding consumables should be selected according to different parent metal.

Welding of Similar Nickel Alloys

1. The welding material you select should be congeneric with the parent metal.

2. If there is no requirement for corrosion resistance, the nickel alloy solder to be selected can be dissimilar with the parent metal. On this occasion, however, welded joint must meet the demands for properties.

Welding of Dissimilar Nickel Alloys and Austentic Stainless Steel

1. Strength and corrosion resistance of the welded seam should meet design requirements.

2. Linear expansion coefficient of the nickel alloy welding material to be selected should be close that of the parent metal.

3. The sensibility to welding crack should be considered.

Welding Attentions

1. Before welding, the welding edge of workpiece and the surface of nickel alloy welding wire must be cleaned up without oxides or other impurities.

2. When you use argon tungsten-arc welding, straight polarity direct current should be adopted; when welding thicker plates, pulsed metal argon-arc-welding by means of direct current reverse polarity or direct current reverse polarity can be employed.

pipe & tubing

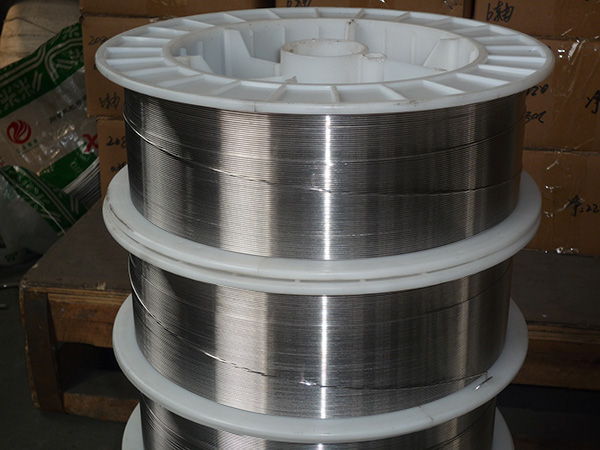

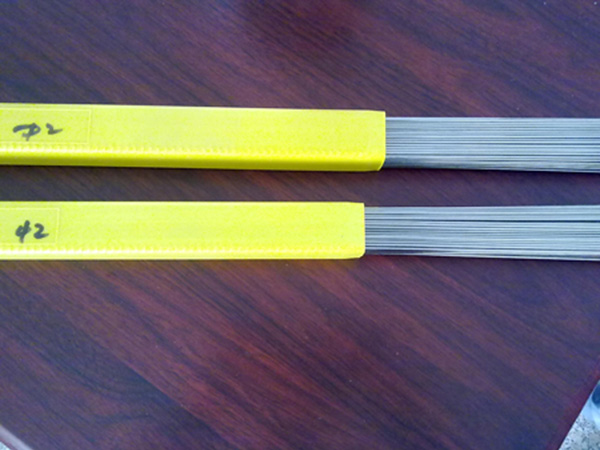

pipe & tubing wire

wire bar

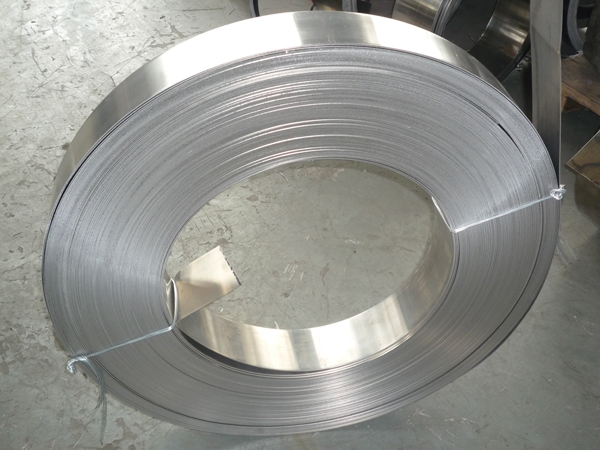

bar sheet & plate

sheet & plate